Bambu Lab A1 Review Begins: What Made Me Finally Upgrade from My Modded Ender 3 v2

3D printing has come a long way in just a few short years. What was once a niche hobby steeped in tinkering and trial‑and‑error is now accessible, affordable, and astonishingly capable. Today’s filament options boast tighter tolerances and performance‑boosting additives, making printing and results much better than in the early days.

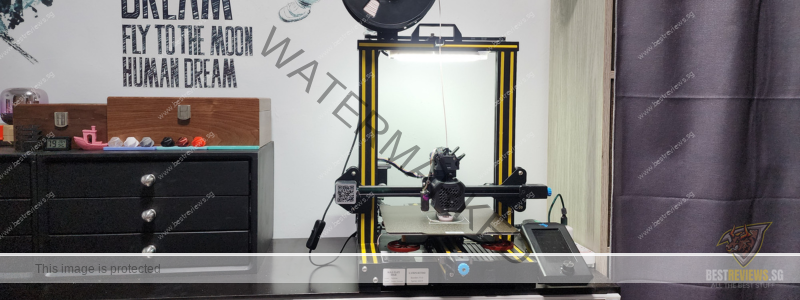

I first stepped into the world of 3D printing in late 2020 with the ever-popular Creality Ender 3 v2. It was an exciting journey filled with equal parts creativity and chaos. When it worked, the sense of accomplishment was unmatched. But when it didn’t, which was often, it demanded time, patience, and a whole lot of tinkering. The Ender 3 v2 was more of a technical project than a tool, from bed levelling issues to extrusion inconsistencies. Over time, I upgraded, modded, and calibrated it to near perfection. It could now deliver surprisingly good prints — but only at a modest speed of around 70 mm/s and with constant supervision.

After four years of late-night calibrations and firmware tweaking, I knew it was time. I wanted a fast, reliable, and intelligent printer that could match my growing expectations: no more manual levelling or temperature games. I wanted plug-and-play efficiency with consistent, high-speed output. And I craved multi-colour capability—something my Ender couldn’t dream of achieving.

My dream printer had to be one that:

- Worked reliably out of the box, with minimal adjustment.

- Printed faster, confidently.

- Handled multi-colour jobs without needing me to babysit.

With a budget capped around SGD 800, I shortlisted four multi-material-ready printers: the Bambu Lab A1 Combo, Creality Hi-Combo, FlashForge Adventurer 5X, and AnyCubic S1 Combo. All were tempting in their own right, but after weeks of research and watching far too many reviews, I pulled the trigger during the 5.5 sale.

The Bambu Lab A1 Combo promised everything I’d been missing — and more. This is the story of how it won me over.

Where it really shines is its ecosystem. The AMS Lite system enables reliable multicolour printing, while Bambu Studio and the MakerWorld app simplify the entire workflow—from slicing to printing—in just a few taps. Smart maintenance reminders and built-in calibration routines ensure consistent performance with minimal effort. Even non-tech users can jump in, print, and enjoy.

Having clocked over 600 print hours myself, I can confidently say the A1 Combo is the 3D printer I always hoped my old Creality Ender 3 v2 would become. It's reliable, easy to maintain, and genuinely fun to use. Whether you're upgrading or diving into 3D printing for the first time, the Bambu Lab A1 Combo is an absolute game-changer.

- Exceptional Out-of-the-Box Experience

- High-Speed, Reliable Performance

- Integrated Multi-Colour Printing (AMS Lite)

- Smart Ecosystem & Software

- Minimal Maintenance Required

- Excellent Print Quality with PLA, PETG, TPU, PVA

- AMS Lite Has Some Limitations (does not support ABS, ASA, PC, PA, PET, Carbon/Glass Fiber Reinforced Polymer)

- Internet Dependency

- Not Fully Open Source

● Net Weight: 8.3 kg

● Build Volume: 256 x 256 x 256 mm³

● Chassis: Steel + Extruded Aluminium

● Max Speed of Toolhead: 500 mm/s

● Max Acceleration of Toolhead: 10000 mm/s²

● Max Power: 1300W@220V, 350W@110V

● Display: 3.5 inches 320*240 IPS Touch Screen

● Connectivity: Wi-Fi, Bambu-Bus

● Storage: Micro SD Card

● Control Interface: Touch Screen, APP, PC Application

Why the Bambu Lab A1 Appeals to Me Over Other Printers?

The Bambu Lab A1 appeals to me over other printers because it represents a fundamental shift from fiddly, hands-on troubleshooting to a genuinely streamlined user-centric experience. After spending over 2,000 hours on my modded Creality Ender 3 v2, I'm no stranger to manual calibration, late-night belt adjustments, and firmware juggling. That machine taught me a lot, but demanded time and effort at every turn. The A1 Combo, by contrast, works. It prints fast, reliably, and with very little intervention on my part. The difference isn't just in the machine—it's in the entire Bambu ecosystem.

What truly sets the A1 apart from similarly priced machines is its level of integration. The MakerWorld app and Bambu Studio slicer are intuitive, intelligent, and delightfully well-thought-out. I no longer waste time adjusting supports or experimenting with slicer settings. Many models on MakerWorld are already pre-optimised by creators, so I download, slice, and print. The convenience this brings is enormous — it allows me to focus on creativity and output, rather than wrestling with the technical hurdles that often plague 3D printing workflows.

What surprises me is how deeply Bambu has considered the everyday user experience. The printer prompts me when maintenance is due and even offers helpful diagnostics when something goes wrong. Gone are the days of decoding vague error messages or mindlessly searching Reddit threads for answers. Whether suggesting a nozzle clean or flagging a clogged filament path, the A1 helps me maintain it proactively, not reactively.

In the end, what I value most is peace of mind. I wanted a “send and forget” printer, and that's precisely what I got. With the A1 Combo, my prints will come out right the first time, every time. It's no longer just about having a capable printer; it's about having an ecosystem that removes friction from every process step. That's why, for me, the Bambu Lab A1 stands head and shoulders above the rest.

The Unboxing Experience of the Bambu Lab A1 Combo

The Bambu Lab A1 Combo set a reassuring tone from the moment I opened the box. Unlike the barebones, DIY-style packaging I'd grown accustomed to with my Ender 3 v2, the A1 Combo arrived in a meticulously organised and thoughtfully packed box. The gantry and base came as separate modules, clearly labelled and intuitively laid out. Screws, tools, and spare parts were all included—and not just thrown in loosely, but neatly arranged in compartments. Even better, QR codes linking directly to official setup videos and documentation were provided, eliminating the usual guesswork.

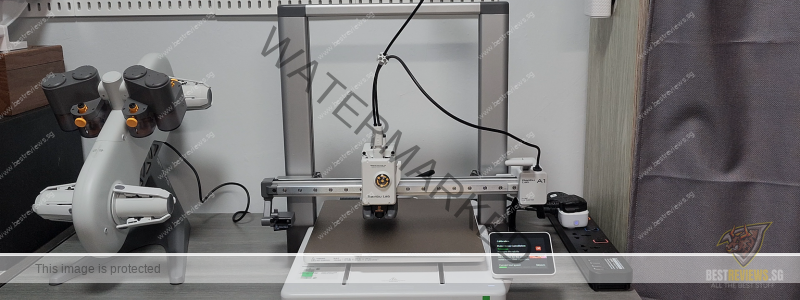

Assembly was refreshingly fast. Within 20 minutes, I had attached the gantry to the base, mounted the AMS Lite to the side, and connected the necessary cables. It felt more like setting up a modern kitchen appliance than building a 3D printer from scratch. No fumbling around with firmware flashes or belt tensioning—just a clean, well-guided process from start to finish.

When I powered it on, the 3.5-inch touchscreen greeted me with a polished animation, followed by a setup wizard that walked me through Wi‑Fi configuration, firmware updates, and auto-calibration. Everything was seamless. By the time I had finished my coffee, the machine was already laying down the first layer of its maiden print.

Ironically, I was disappointed by how little effort it took. After years of wrenching, levelling, and tweaking, this felt… too easy. But that's the beauty of it. The A1 Combo doesn't ask for your time—it gives it back.

Initial Thoughts on Design and Build Quality

The Bambu Lab A1 looks and feels like a premium product. The full-metal frame is solid and well-machined, with clean cable management and neatly enclosed components. The design is minimalist but functional, with a 3.5-inch IPS touchscreen taking centre stage. Even the AMS Lite attachment, which holds four filament spools, feels more like a purpose-built accessory than an afterthought.

Every moving part operates smoothly. The motion system is responsive and quiet, with steel rods and linear bearings showing no wobble or play. The magnetic PEI-coated build plate snaps with satisfying precision, and the nozzle assembly locks into position with a magnetic latch. This isn't a printer you need to babysit or tinker with daily.

Speed, Precision, and Sensor Technology

What truly separates the Bambu A1 from the pack is its speed and sensor-driven intelligence. Out of the box, it prints at up to 500 mm/s with accelerations up to 10,000 mm/s². These numbers might sound extreme —and they are — but the results are immaculate. I expected ringing, ghosting, or layer shifts at these speeds, but the A1's active vibration compensation and flow rate sensors kept everything sharp and consistent.

The printer uses an eddy-current sensor to analyse the movement of the toolhead and compensate in real time. Coupled with motor noise cancellation and auto bed levelling, the result is a machine that seems to correct itself before you even notice an issue. During my first week, I printed complex models with intricate overhangs and tight tolerances, and they all came out looking like they were produced on a much more expensive system.

Multi-Colour Printing with AMS Lite

One of the biggest reasons I chose the Bambu A1 Combo was its ability to print in multiple colours or materials easily. The AMS Lite module supports up to four spools, automatically loading and unloading filaments as needed. It reads RFID tags (on supported spools) to detect material type, and it handles everything from PLA and PETG to TPU and carbon-fibre blends.

Printing multi-colour models was a nightmare with my Ender 3 v2 — involving manual pauses, filament swaps, and g-code tweaking. With the AMS Lite, it's seamless. The system purges a small amount of filament during colour changes, which results in some waste, but this is a small price to pay for the convenience. I load the model into Bambu Studio, assign colours, and let it run. Watching the printer automatically switch materials mid-print feels borderline magical.

Software Experience

Bambu Studio is a polished, modern slicer that integrates deeply with the A1 ecosystem. It supports real-time monitoring, firmware updates, and even cloud-based control. The UI is clean, the profiles are well-tuned, and it's incredibly easy to assign materials, tweak settings, or preview toolpaths. Compared to the patchwork of community-developed slicers I used with the Ender 3, this feels like a breath of fresh air.

The only caveat is that the A1 is tightly integrated into Bambu's ecosystem. You can't use third-party firmware or alternative slicers without significant workarounds. For some, this might feel restrictive. But for me, the convenience and stability outweigh the limitations. It just works.

Real-World Performance

Over the past few weeks, I've printed everything from mechanical parts and articulated figures to lithophanes and vases. The A1 has handled it all with ease. Dimensional accuracy is excellent, surface quality is smooth, and layer consistency rivals that of far more expensive machines.

Prints that took over four hours on my Ender 3 V2 now finish in less than 90 minutes. And they look better, too. Supports are easier to remove, bridging is cleaner, and first-layer adhesion is rock-solid. Even prints with tight-fitting parts assemble correctly on the first try.

Maintenance and Upkeeping of the Bambu Lab A1

Effortless Maintenance from Day One

After logging more than 600 hours of print time on the Bambu Lab A1, its upkeep is minimal. Coming from a Creality Ender 3 v2—where maintenance often felt like an ongoing project — the A1 has transformed what used to be a chore into a straightforward routine. Everything about its design, from the accessible nozzle to the flexible PEI build plate, encourages easy care and quick interventions.

Smart, Usage-Based Maintenance Reminders

What impresses me most about the A1 is its built-in maintenance reminders. These aren't just vague pop-ups but intelligently triggered based on actual usage. The printer notifies me with precise, actionable prompts, whether it's time to clean the nozzle, lubricate the Y-axis rods, or inspect the extruder. Most of these tasks take less than five minutes to complete, making regular care feel effortless rather than burdensome. This proactive approach means the printer stays in peak condition without constant monitoring.

Going Beyond the Basics

Even with automated reminders, I like to go the extra mile. Rather than waiting for the prompts, I periodically maintain all three axes— X, Y, and Z — to ensure everything remains smooth and precise.

This small investment of time pays off with quieter operation, cleaner movements, and consistent print quality, especially during high-speed or multi-material jobs. The A1's accessible components make preventative maintenance far easier than on other machines I've owned.

Build Plate Care Made Simple

Bed adhesion and surface quality are vital for any 3D printer, and the A1 makes it easy to preserve both. I avoid touching the build plate directly with my hands, using gloves or a clean cloth to prevent oils from transferring to the surface. After each print, I give the plate a quick wipe with an alcohol swab to remove residue.

And every 20 prints or so, I wash it thoroughly with warm water and dish soap. This routine keeps the plate surface flawless and extends the life of the plate—an essential but often overlooked part of maintenance.

Why It Matters

With its smart reminders and accessible design, the Bambu Lab A1 transforms maintenance from a fiddly afterthought into an integrated, user-friendly part of the 3D printing process. It's not just a high-speed, high-quality printer—it's a machine designed to stay that way, with minimal effort on your part.

Downsides and Considerations

No machine is perfect, and the A1 does have a few quirks. The AMS Lite increases the printer's footprint and doesn't handle wide spools or very stiff filaments particularly well. The lack of a USB port is mildly annoying for those who prefer wired connections. And the cloud-centric design may not appeal to users who prefer complete local control.

There's also some filament waste involved with colour changes, and the printer's enclosure is unsuitable for high-temp materials without modification. That said, these issues are minor compared to the overall experience. For every frustration I had with my Ender 3, the A1 has provided a deliberate and refined solution.

Editor's Final Thoughts: Is the Bambu Lab A1 Combo Worth It?

Absolutely. The Bambu Lab A1 Combo is the 3D printer I always wished my modded Creality Ender 3 v2 would evolve into, but never quite managed. The A1 is fast, whisper-quiet, and exact, yet demands almost no babysitting. Whether I'm printing intricate models, running high-speed batches, or switching materials using the AMS Lite, the A1 handles it without hesitation. It's been engineered to print well and eliminate the fiddly friction points that long defined the 3D-printing hobby.

What truly sets the A1 Combo apart, beyond its impressive hardware, is the seamless integration of its ecosystem. Bambu Studio is genuinely a joy to use. MakerWorld takes care of model sourcing and setup; even the mobile app feels like it was designed with real people in mind. It's not just about slicing files and tweaking retraction speeds anymore—it's about walking into your workspace, hitting ‘print', and getting consistent, high-quality results. And the fact that my spouse, with no previous experience, can now confidently operate the printer speaks volumes.

The A1 doesn't just feel like a tool for hobbyists—it feels like a proper home appliance. It prompts me when maintenance is due, offers intelligent diagnostics when things go wrong, and has completely removed the guesswork that once plagued my printing process. After spending hundreds of hours with it, I can't imagine returning to the older ways of doing things. It's changed the way I make and how much I enjoy the process.

If you're looking to stop wrestling with outdated firmware, manual bed levelling, or endless trial and error, the Bambu Lab A1 Combo is your way forward. I love the ease. I love the polish. I love the consistency. But more than anything, I love that it makes 3D printing feel like fun again and that, to me, is priceless.