Why I Began 3D Printing at Home

When I first stumbled upon 3D printing in 2020, it felt like a glimpse into the future — like owning a Star Trek replicator, minus the teleportation. I'd always enjoyed making things, whether it was DIY crafts, small home projects, or tinkering with gadgets. The idea of printing anything—from phone stands to camera accessories — right from my desktop was irresistibly appealing.

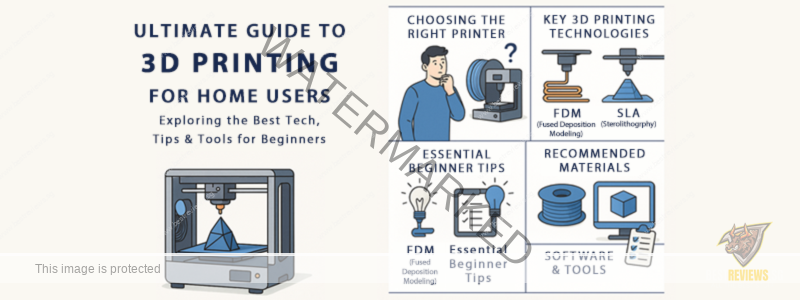

But diving into home 3D printing wasn't as straightforward as clicking ‘Print'. There were countless technologies, confusing acronyms like FDM, SLA, SLS, and many machines, all promising the “best” results. I wanted a straightforward guide that would break it all down: what each technology does, which one makes the most sense for home use, and how to choose one that fits my budget, space, and goals.

After years of hands-on experience, testing multiple printers and materials, and keeping up with industry innovations, I've crafted this comprehensive Guide to help you get started correctly.

Understanding the Main Types of 3D Printing Technologies

Before we talk about what's best for the average home user, it's crucial to understand the broad landscape of 3D printing technologies. There are seven major categories, but only a few are viable for home use in terms of cost, safety, and practicality.

1. FDM (Fused Deposition Modelling) – The Home User's Favourite

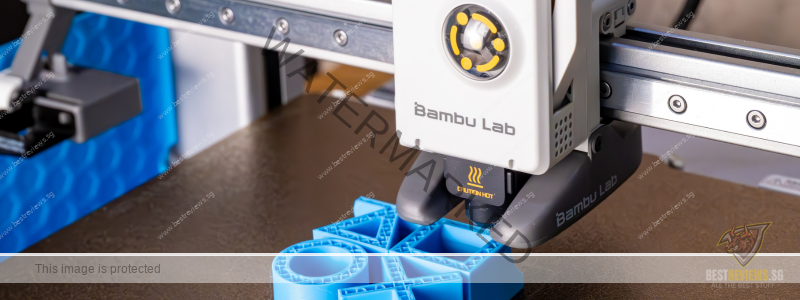

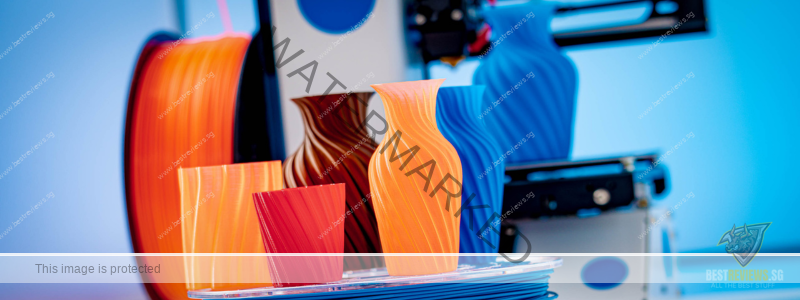

FDM is the most popular 3D printing technology for home and personal use. It works by heating a thermoplastic filament (such as PLA, PETG, or ABS) and extruding it through a nozzle layer by layer to form the object.

When I first got into 3D printing, I started with a Creality Ender 3 V2 — an FDM printer that's affordable and widely supported by the community. While FDM doesn't offer the finest detail, it's perfect for printing functional parts, toys, home organisers, and cosplay props.

Materials like PLA, PETG, and TPU are inexpensive and easy to work with, making FDM the top choice for most home users.

- Pros: Affordable, widely available, user-friendly, and compatible with many filament types.

- Cons: May show visible layer lines; not ideal for very fine or highly detailed prints.

- Best For: Prototyping, functional parts, toys, hobby projects, and beginners.

2. SLA (Stereolithography) – For High Detail and Smooth Finishes

SLA printers use UV light to cure liquid resin into solid layers. The prints are smoother and more detailed than those from FDM printers, but working with resin is messier and requires post-processing (like washing in isopropyl alcohol and curing under UV light).

SLA is best if you're into miniatures, jewellery, or dental models — anything requiring intricate detail.

- Pros: Exceptional print resolution and surface quality; excellent for miniatures or jewellery.

- Cons: Resins can be messy, smelly, and require post-processing (like washing and curing); printers and materials are often more expensive than FDM.

- Best For: Artists, dental models, intricate miniatures, jewellery, and detailed figurines.

3. MSLA (Masked Stereolithography) – The Most Common Resin Variant

A more modern and cost-effective variant of SLA, MSLA uses an LCD screen as a light mask, exposing entire layers simultaneously rather than tracing them with a laser. Most desktop resin printers today are MSLA.

My first dabble with MSLA was the Creality Halot Mage 8K Resin Printer at a workshop. This is a brilliant machine in terms of quality. However, the resin fumes and the cleaning process were not ideal for indoor use in a small flat. SLA is best if you're into miniatures, jewellery, or dental models—anything requiring intricate detail.

- Pros: Faster and more affordable than traditional SLA; excellent detail; many budget-friendly models available.

- Cons: Same resin handling drawbacks as SLA.

- Best For: High-resolution models, tabletop gaming miniatures, and creative arts.

4. SLS (Selective Laser Sintering) – Professional but Powerful

SLS uses a laser to fuse powdered nylon (or other materials) into solid objects. It doesn't require supports, making it ideal for complex geometries.

- Pros: Strong, functional parts with excellent mechanical properties.

- Cons: Expensive and primarily found in industrial or commercial settings.

- Best For: Engineering-grade prototyping, enclosures, hinges, and internal mechanisms.

5. Other Less Common Types

- Binder Jetting, EBM, DED: These are highly specialised techniques involving powdered metals, ceramics, or composites. Not suitable for home use due to cost and complexity.

- DLP (Digital Light Processing): Similar to SLA, but uses a projector instead of a laser or LCD. Offers speedy print times and excellent detail. Primarily seen in dental and commercial use.

- MJF (Multi Jet Fusion): Developed by HP, MJF is similar to SLS but offers finer detail and faster throughput. Primarily used in industry.

3D Printing Technology Comparison Chart

| Feature / Type | FDM | SLA / MSLA | SLS |

|---|---|---|---|

| Print Method | Melts plastic filament layer by layer | Cures liquid resin using light | Sintering powder with a laser |

| Materials Used | PLA, PETG, ABS, TPU, etc. | Photopolymer resins | Nylon, TPU powder |

| Print Quality | Good (visible layer lines) | Excellent (smooth, high detail) | Very good, strong mechanical parts |

| Print Speed | Moderate to Fast | Moderate | Fast |

| Ease of Use | Beginner-friendly | Intermediate (resin handling needed) | Advanced (requires training) |

| Maintenance | Low to moderate | Moderate to high (cleaning, curing) | High |

| Post-processing | Minimal (support removal) | Required (washing, curing) | Cleaning, powder recovery |

| Printer Cost (SGD) | ~SGD350 – 2,000 | ~ SGD220 – 1,200 | SGD5,000+ |

| Material Cost (SGD/kg) | ~SGD15 – 50 (filament) | ~SGD50 – 100 (resin) | ~SGD100 – 300 (powder) |

| Best For | Functional parts, prototypes, DIY | Miniatures, jewellery, fine details | Industrial parts, complex shapes |

| Space Needed | Desktop or small shelf | Ventilated workspace (small) | Dedicated room or lab |

What's the Most Suitable 3D Printing Technology for Home Users?

So, with all that tech jargon out of the way, what's suitable for your average home setup?

After extensive experience, here's my clear takeaway:

- Best for beginners: FDM

- Best for artistic detail: MSLA

Budget & Cost of Entry

FDM Printers

You can find a reliable FDM printer in the SGD $270 to $900 range for home use. Notable options include the Creality Ender 3 V3 SE, Anycubic Kobra, and the Prusa Mini+, all of which are open-source, well-supported by the community, and excellent for those who enjoy tweaking and customising. The Bambu Lab A1 Mini is another standout choice, offering a more polished plug-and-play experience at an affordable price.

Filament costs are generally manageable — a standard 1kg spool of PLA filament typically costs between SGD 15 and SGD 25. It will last for several medium-sized prints depending on your project's complexity.

MSLA Printers

For those interested in high-detail printing, an entry-level MSLA (Masked Stereolithography) printer such as the Anycubic Photon Mono X, Elegoo Mars, or Creality Halot R6 usually costs between SGD 220 and SGD 600, depending on resolution.

However, it's essential to consider the additional costs. Resin tends to be more expensive than filament, typically priced at SGD 45 to SGD 90 per litre. On top of that, you'll need post-processing equipment (such as a wash and cure station), isopropyl alcohol, and protective gear like gloves and safety goggles.

While resin printers deliver beautifully detailed results, they tend to rack up more hidden costs over time, from consumables to cleaning supplies. They may look sleek on your desk, but their maintenance and operational needs can quickly exceed those of FDM printers.

Ease of Use & Maintenance

FDM has come a long way if you want a plug-and-play experience. Auto bed levelling, silent stepper motors, and direct drive extruders (like on the Bambu Lab A1) make printing intuitive and joyful.

MSLA printing, in my opinion, is more surgical. You'll need gloves, a wash station, and a dedicated post-cure setup. It's not difficult, just more involved.

Materials & Applications

- FDM offers the widest material range: PLA for beginners, PETG for stronger parts, TPU for flexible prints, and ABS for heat resistance.

- MSLA materials tend to be more specialised — great for dental, jewellery, or display models, but brittle for functional use.

My Setup and Workflow

Currently, I'm using a Bambu Lab A1 Combo, which combines speed, quiet operation, and multi-colour printing via AMS Lite. It's the first time I've stopped tinkering and started printing on demand.

My typical print flow:

- Design in Fusion 360 or download from Makerworld.com (Bambu Lab's online community) or Printables.com

- Slice with Bambu Studio

- Print via WiFi or mobile App, monitor progress remotely

- Use parts straight off the bed — minimal post-processing

If you're starting out, I'd suggest pairing a solid printer with:

- A few good storage boxes for your filament

- OctoPrint or Bambu Handy App (if you are using Bamb Lab's printer) for monitoring

- Cura, PrusaSlicer, or Bambu Studio for slicing

Common Beginner Pitfalls and How I Overcame Them

Bed Levelling

Manual bed levelling was the bane of my existence. Invest in a printer with automatic bed levelling—it's worth every pound.

Warping and Adhesion

PLA warps less, but still needs good bed adhesion. A PEI sheet changed my life. Use glue stick or Magigoo for PETG.

Failed Supports

Use tree supports and paint-on support placement in your slicer. It gives you better control and saves material.

First Layer Troubles

Your first layer is everything. Take the time to tune Z-offset and flow rates. Don't rush it—slow and steady gives the best results.

Sustainability and Noise Considerations

- Noise: FDM printers can be noisy. Go for one with silent stepper drivers (TMC2209 or similar). Resin printers are quieter but smellier.

- Energy use: FDM is generally more energy-efficient unless printing huge parts.

- Waste: Resin prints generate more waste due to supports and isopropyl alcohol use. FDM is better for home use in terms of environmental friendliness.

How to Choose the Right 3D Printer

Choosing your first 3D printer can be overwhelming. However, it becomes much easier to pick the right one once you narrow down your needs, available space, and budget. Here's a step-by-step guide to help.

Step 1: Define Your Purpose

Ask yourself: What do I want to print?

- Functional parts and prototypes (e.g. brackets, tools, enclosures):

- Go with FDM. It's affordable and versatile, and it prints strong parts using materials like PLA, PETG, or ABS.

- Miniatures, figurines, or high-detail models (e.g. D&D characters, jewellery):

- Choose SLA/MSLA. Resin printers offer far superior detail and surface quality, which is ideal for artistic work.

- Engineering-grade parts or professional rapid prototyping:

- Consider SLS—though it's far beyond home use in most cases.

Step 2: Consider Your Workspace

- FDM printers can be set up on a standard desk, dining table, or shelf. They don't require ventilation but produce some noise and smell (especially with ABS).

- Resin printers (SLA/MSLA) need a well-ventilated area or a fume extractor. You'll also need space for a wash and cure station, and surfaces that can handle accidental resin spills.

- SLS requires a dedicated workshop or lab and industrial-level safety practices, which are unsuitable for a home environment.

Step 3: Assess Your Budget

- Under SGD 500: Solid FDM options include the Creality Ender 3 series, Anycubic Kobra, or Elegoo Neptune.

- SGD 500–900: This range gets you faster, more innovative FDM printers like the Bambu Lab A1 Combo or resin printers like the Anycubic Photon M5 or Elegoo Saturn.

- SGD 1,000 and above: You'll find premium resin machines or advanced FDM printers with features like multi-colour (AMS) such as Bambu Lab P1S, vibration compensation, AI inspection, and better build quality.

Step 4: Consider Print Size & Frequency

- Small prints once in a while? A compact resin printer or a budget FDM printer is fine.

- Daily prints or larger projects? Go for a full-size FDM printer with auto-levelling and better heat management, like the Bambu Lab A1 or Prusa MK4.

- Need to run overnight? Choose a quiet, reliable machine with a filament run-out sensor and print recovery. Bambu printers excel in this regard.

Step 5: Think Long-Term

Don't just buy for now; buy where you're headed. Consider:

- Ease of upgrades (e.g. better nozzles, AMS attachments)

- Community support and ecosystem

- Software integration (ease of slicing, remote monitoring, firmware updates)

- After-sales support or parts availability in your region.

Editor's Final Thoughts: Which 3D Printing Tech Should You Choose?

If you're just beginning, go FDM. It's the sweet spot between cost, learning curve, safety, and community support.

If you're an artist or designer who needs high detail, resin SLA is your friend—but be prepared for post-processing.

If you need strength and durability, use SLS — but outsource it for now.

No matter your path, 3D printing opens a world of creativity and practical problem-solving. There's nothing like watching a digital design come to life on your desk.